Table of Contents

Warehouse inventory management solutions can make a major difference in your business revenue. Wondering How?

The success of your ecommerce business is intricately linked to the streamlined execution of warehouse operations and adept inventory management, directly impacting your financial performance.

Warehouse and inventory management systems are crucial, ensuring precise stock control, avoiding stockouts, and minimizing surplus for a finely tuned supply chain process and enhanced profitability.

The indirect effects of WMS and IMS solutions are more impactful- keeping top of warehouse management solutions ensures prompt delivery of the products. This in return boosts customer satisfaction and increases retention rate which ultimately reflects in your business profits.

Are you also looking for a smart Warehouse Inventory Management Solution? RockEye WMS is an All-In-One Next-Gen Automated Warehouse and Inventory Management Solution redefining the operations!

Let’s watch the quick video to know “Guide To Warehouse Inventory Management Solution”

A Complete Guide To Warehouse Inventory Management Solution

Why Does Warehouse Inventory Management System Matters To Your Business?

With lots of products and materials moving through warehouses, it’s complex to manage and monitor every task with a traditional warehouse management model. Though the physical and financial conditions of warehouses can have a great impact on your business, therefore, retailers and other businesses prefer shifting to automated warehouse management systems to maximize their efficiency.

“According to studies, it is noticed that using the integrated order processing systems in Inventory management can boost productivity by 25% and enhance space consumption by 20%.”

The automated Warehouse inventory management solutions are designed to transform operations and streamline order fulfillment, reducing operational costs and improving customer satisfaction.

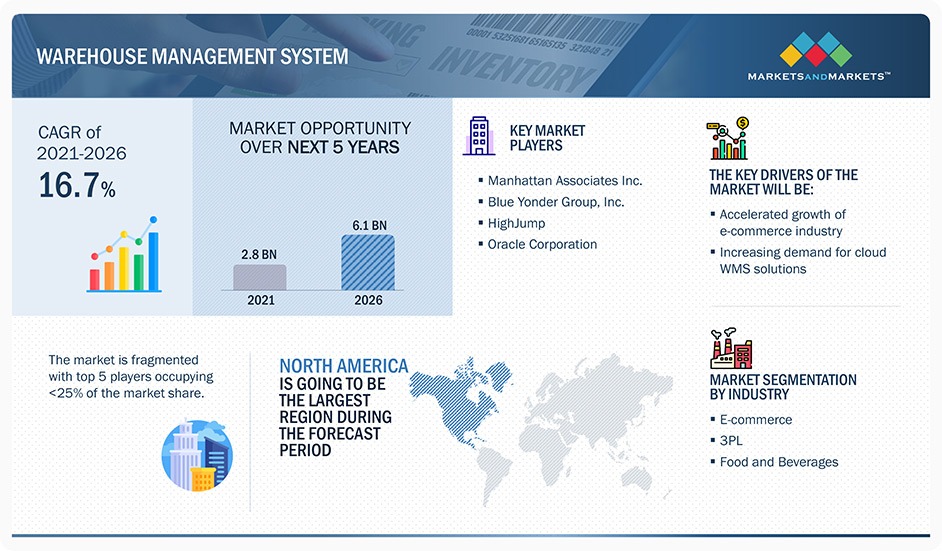

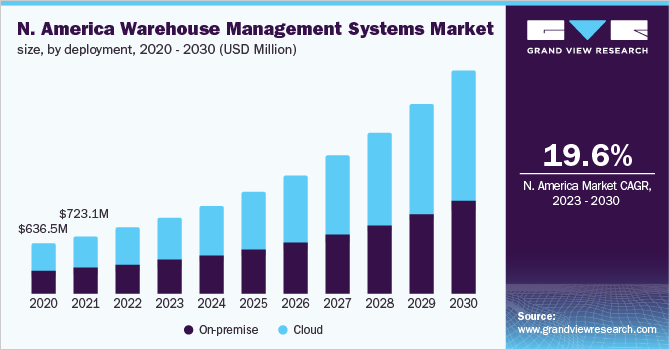

This is why the demand for warehouse management solutions is surging. It is expected that WIMS will make a market size of $7.30 billion by 2030.

Apart from here are some crucial benefits that businesses can avail by having the best Warehouse Management Solution in place:

- Faster Inventory Turnover

- Enhanced Customer and Supplier Relationships

- Warehouse Personnel Reduced

- Better Stock Control

- Optimized Warehouse Space

- Improved Labour Productivity

- Reduce Operating Expenses

- Strengthen Security

- Optimize Inbound and Outbound Logistics

- Enhance Billing Management

Any top software development company in India can help you customize your Warehouse inventory management solution to streamline your operations. But before that, you need to understand the concept of Warehouse Inventory Management Solution and its challenges.

Explore our Inventory Management Solution now!

Empower your Warehouse with Precision and ControlWhat is a Warehouse Inventory Management Solution?

A Warehouse Inventory Management Solution (WIMS) is a comprehensive software system mindfully designed to oversee and optimize all the aspects of inventory within a warehouse. Right from tracking, organizing, and managing inventory levels to ensuring accurate stock information, and streamlining various warehouse processes are the core functions of WIMS systems.

In fact, with these solutions, retailers can monitor the process from buying raw materials to the production of final items. Though these are the basics of warehousing, therefore wholesalers, distributors, retailers, and ecommerce sellers are looking for powerful WMS solutions to maintain transparency in operations and to ensure satisfaction to customers.

Inventory often counts as a crucial asset of any warehouse. And when it comes to managing the inventory in multiple warehouses although in different locations, then the task will become highly challenging.

That’s where warehouse inventory management solutions take place. “Warehouse Inventory Management Solutions enable real-time stock monitoring, minimizing errors and enhancing operational efficiency. With features like order fulfillment and inventory tracking, businesses maintain optimal stock levels and improve order accuracy.”

Implementing a WIMS contributes to accuracy in analytics and helps you proceed with the real stock projections. Ultimately, you will have the right amount of products on hand to meet sales and avoid excessive buildups.

But before you hire an app developer in India to get started with WMS, let’s understand the core concept of warehouse management and inventory management.

Difference Between Warehouse Management Vs. Inventory Management

Warehouse management and inventory management are two different aspects of supply chain management. However, together they play a crucial role in enhancing overall operations.

Inventory Management

Inventory Management is all about making decisions related to stock based on expected demand. It takes a business-level approach and encompasses not only the finished products in storage but also goods in storefronts and raw materials during the manufacturing phase. Utilizing the broad view analytics, businesses can appropriately manage the overall stock levels and be able to meet market demands. Having the right data in hand, actually minimizes the risk of over or shortage of stock.

Warehouse Management System (WMS)

WMS focuses on the detailed processes within warehouse operations. It optimizes stock storage, handles picking and packing tasks, and ensures overall operational efficiency. WMS is concerned with the minutiae of managing finished products in storage until they are ready for sale. This includes tasks such as prioritizing items based on factors like expiration dates to minimize waste and streamline the order fulfillment process.

To summarize:

Inventory Management provides a high-level overview of everything related to stock, from acquisition to sale, encompassing various stages and locations. On the other hand, the Warehouse Management System involves into managing and overseeing the warehouse functionality, and handling of finished products until they leave storage.

Warehouse Management System (WMS):

- Controls all aspects of warehouses – including spaces bins, shelves, rooms, and movement of goods, and products.

- More complex and includes functions like production and sales management.

- Supports the creation and designation of SKUs, as well as kitting (combining multiple SKUs into a package under a new SKU).

- Manages and optimizes every aspect of warehouse operations.

- Granular, capable of locating specific items within the warehouse.

- Often used by larger organizations with multiple warehouses and a diverse product range.

- Enables omnichannel selling by tracking and controlling inventory across various online platforms and physical selling points.

Inventory Management System (IMS):

- Specializes in managing and counting individual items or SKUs in warehouses.

- Less complicated and used as standalone solutions in small to midsize organizations with a limited product range.

- Tracks total amounts of inventory in specific warehouse areas.

- Provides quantity information of SKUs in the warehouse but may lack granular details like specific bin locations.

All in all, together they contribute to a streamlined and effective supply chain management process.

Unlock Seamless Inventory Control

What are the Three Major Inventory Management Techniques?

Warehouse inventory management involves systematically tracking stored products and goods. Typically overseen by a warehouse manager, it ensures transparency across receiving, storing, moving, processing, and delivering. The manager ensures the safe and organized execution of these processes, maintaining optimal inventory levels.

Three Major Warehouse Inventory Management Techniques

- Push system for inventory management

- Pull system for managing inventory

- Just-in-time inventory management system

Warehouse Inventory Management Methodologies

So what are the warehouse inventory management methodologies involved in the systems that help in reducing operational costs, the hassle of managing inventory, and tracking the stock levels?

It includes various techniques including ABS analysis, FIFO/LIFO, Just-In-Time, RFID integration, and more to overall improve the supply chain performance.

So let’s discuss in detail how each technique works:

- Cross-Docking

Cross-docking is an efficient inventory management strategy and helps to receive and load docks facing each other with goods transferred from one to another. In cross-docking, the receiving dock is loaded while the sending dock is unloading. This allows cross-docking to be as efficient as possible. Because of cross-docking, the docks never need to be loaded from both ends simultaneously.

- Two-bin Method

In this two-bin system, you would put the working stock of the item in the working bin in the reserve bin when storage is nearing capacity to have more working stock on hand at any time. The other method called the single-bin method, involves storing your working stock of an item in one bin and your reserve stock in another.

Looking to streamline your warehouse inventory management? Hire top mobile app developers in India to implement efficient methodologies tailored to your business needs.

- Fixed Order Quantity

With fixed-order quantity, you can order exactly what you need when you need it, without the stock sitting on the shelf. By reducing wasted inventory, you can meet the demands of high-volume customers more quickly and reduce the need for daily restocking.

- Fixed-Period Ordering

Also known as FPO or simply the FPO method, this technique ensures the same quantity is always placed on the same day.

Despite the repetition, the fixed-period order remains a viable form of ordering. It is common to repurpose these orders for other purposes, such as managing volatility or calculating the cost of a trade.

The fixed-period order is a trade form closely tied with inventory control and, ultimately, stock-keeping, which are fundamental business processes. By understanding this technique, an asset manager learns how to manage inventories and reduce the risk of fast-selling items sitting on the shelf. It can also eliminate the need to purchase back inventory and better match supply and demand.

- Vendor-Managed Inventory

Vendor-Managed Inventory is a modern strategy for meeting high-volume product or service demand. Companies adopt this approach when anticipating rapid sales, allowing vendors to coordinate and manage inventory levels effectively by directly communicating with suppliers.

- Drop-Shipping

Drop-Shipping streamlines inventory management by eliminating the need for stock. Upon customer order, you purchase items from suppliers who directly ship to customers, minimizing storage costs. This method enhances efficiency by bypassing the traditional warehousing process.

Challenges that Businesses Are Chasing With Existing WMS

25% of warehouses are already using the WMS solution. But the question is how far they are satisfied?

Businesses often grapple with challenges related to existing Warehouse Management solutions, including outdated technology, integration complexities, inadequate scalability, and difficulties adapting to evolving supply chain demands.

Addressing these issues is important to attain efficiency and competitiveness. so before we jump into the market to hire software developers in India, let’s uncover the challenges that warehouse owners are chasing.

- Inventory Aging: Poorly designed WMS can leave the scope of mismanagement of aging inventory which can lead to increased costs and potential loss, impacting profitability.

- Security Concerns: Vulnerabilities in existing WMS may risk data breaches, allow for unauthorized access, and fail to integrate systems with security protocols that may affect the sensitive information of your business.

- Cost Management: Inefficient cost control within WMS may result in higher operational expenses and enable to optimization of resource allocation for improved profitability and financial sustainability.

- Data Loss: Inadequate backup protocols in WMS can result in losing historical records. This will create a hassle in decision-making processes and make it challenging for businesses to project future strategies.

- Inaccurate Data: Inaccuracies in WMS data may lead to operational inefficiencies. Accuracies in inventory can end up with overstocking a surplus of stock or failure to fulfill the orders in time.

- Lack of Scalability: WMS scalability is the major issue that businesses may encounter. If it restricts the adaptability to growing business needs then your system fails to manage increasing inventory volumes and orders.

- Offline Tracking: WMS limitations in offline tracking disrupt real-time visibility, causing delays in decision-making, especially in remote environments.

- Poor Visibility: Traditional existing WMS usually leads to poor visibility into inventory, order statuses, and warehouse performance, hindering strategic decision-making and emphasizing the importance of robust reporting and analytics features.

- Stock Control: WMS challenges in stock control result in overstocking or stockouts, affecting cash flow and customer satisfaction, necessitating improved stock management strategies for enhanced warehouse optimization.

Read More: How Warehouse Inventory Management Solutions Facilitate Business Growth and Expansion?

So how will you get the right warehouse inventory management solution for your business for your business?

Choosing the Right Warehouse Inventory Management Solution for Ecommerce

While there are a plethora of WIMS available in the market that come with different price tags and functionalities. But choosing between all those options is always challenging. So this is where you need to evaluate the offering features and integration capabilities of WIMS.

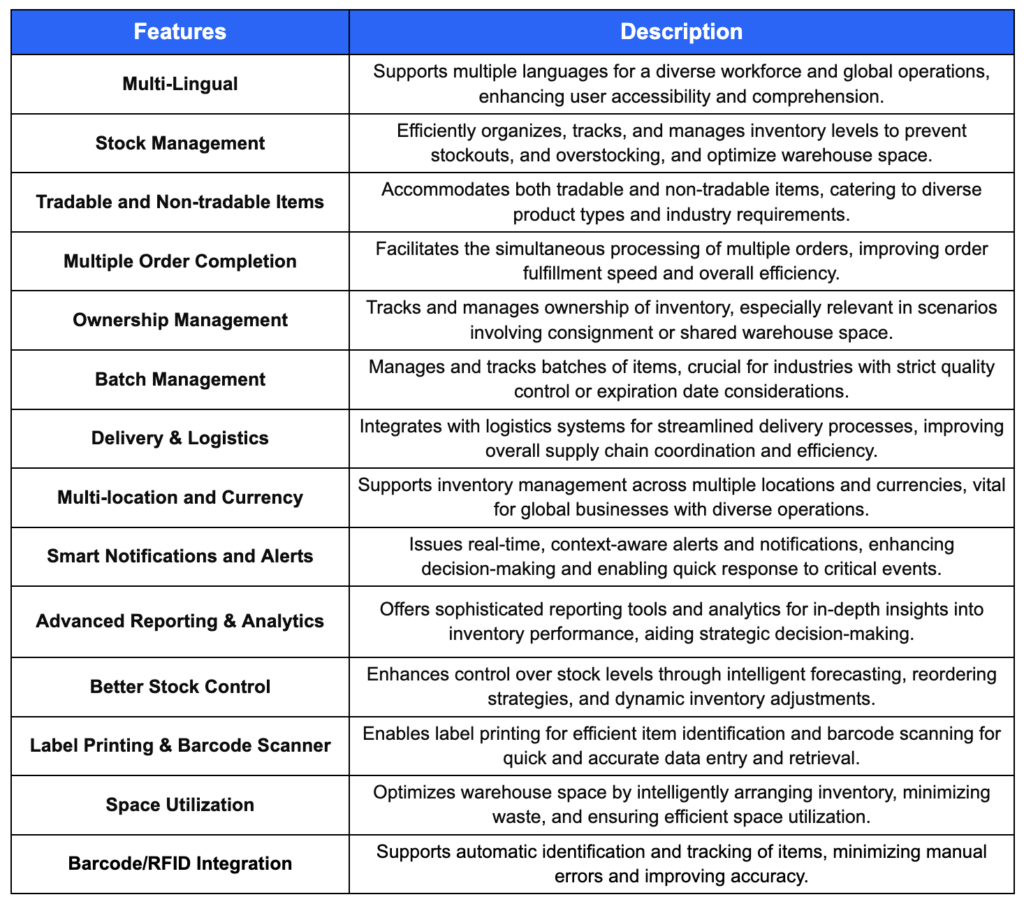

- Warehouse Inventory Management Features

When it comes to choosing the best warehouse inventory management solution, make sure the WIMS has these features available.

Though features are a crucial factor, there are other things that you need to focus on while selecting the WIMS for your business…

Other Parameters To Consider When Choosing The Best Warehouse Inventory Management Solution.

- Integration Capabilities: Go for a Warehouse Inventory Management Solution that seamlessly integrates with your ERP, CRM, Financial Accounting, Procurement, Production Management System, Sales Portal, Generic Sales & Invoicing, and more software. This ensures streamlined data flow, reducing errors and enhancing overall operational efficiency.

- Cross-Platform Mobility: Prioritize a WIMS compatible with iOS, Android, Windows, and web browsers. This cross-platform flexibility empowers your team with real-time access to inventory information and transactions on any device, boosting productivity.

- Real-Time Updates and Alerts: Real-Time Updates and Alerts: Choose a WIMS that triggers instant alerts and notifications to keep your team informed, enabling swift responses to changes and proactive issue prevention.

- Cloud-Based Solution: Consider a cloud-based WIMS for enhanced accessibility and scalability. Cloud deployment allows remote access, fosters collaboration, and eliminates the need for significant hardware investments, offering a cost-effective solution.

Ready to take your warehouse operations to the cloud ecosystem? Here you can enquire about our “RockEye Warehouse and Inventory management solutions” are ready to install SaaS-based custom solutions to redefine your operations!

Best Practices to Build an Efficient Warehouse Management Solution

Implement efficient warehouse management practices by prioritizing inventory, conducting regular audits, and tracking sales for optimal performance and profitability.

- Prioritize Your Inventory

The first step in managing your inventory is to establish what inventory items are integral to the successful operation of your business and which are causing it to lose money or otherwise underperform.

Beginning with what you already have and then adding new inventory can be the first step in turning a losing inventory situation into a winning one.

- Regular Inventory Audit

An audit can uncover hidden costs, reduce waste, improve inventory management and help you save money. When you regularly audit your inventory, you can determine what types of inventory items you should be keeping for your company so you can meet your needs and your goals as a business.

- Track Sales

Tracking sales is another seemingly obvious trick that can help manage inventory. Tracking sales is not just about setting goals and keeping tabs on the percentage reached. It is also about identifying trends, seeing where there is an area of weakness, and planning a strategy to correct that area. It is about noticing when a new market opportunity emerges and learning when to commit and on what terms.

Invest in Automation Solutions!

Let’s build together!

How Do Hidden Brains Help You Get Started With Better WMS and IMS?

Are you all set to embrace the culture of embracing the change in your warehouse operations to overall improve operational efficiency and productivity? If yes, then Hidden Brains can be your trusted WIMS solution development partner.

Whether you are a distributor, wholesaler, or retailer managing the products and goods, looking to build a WMS, you should consider hiring a software development company in India that has the right capabilities for your needs. No one-size solution fits all, therefore, you need to evaluate your business requirement first and then proceed to WMS.

At Hidden Brains, we have built the right solution for multiple warehouses with the innovation, functionality, and versatility they need to grow and thrive.

We have the required skills and expertise to build customizable warehouse software solutions to help you track your inventory, print labels, and seamlessly operate across different channels.

So whether you are looking for ready-to-use SaaS-based WIMS or customized solutions, we have covered all the solutions for you. For more details, you can drop a query below or contact us!

FAQs

If you still have a query or confusion about the warehouse inventory management solution, then you can consider this FAQs section to get detailed information.

Is Our Warehouse Inventory Management System Integrated With Other Systems?

Yes, our strategically and mindfully designed warehouse management system is flexible and capable of integrating with various solutions including Financial Accounting, Procurement, Production Management System, Sales Portal, Generic Sales & Invoicing, and more.

Does Your Warehouse Inventory Management Solution offer Mobile Accessibility?

Yes, our WMS and IMS systems are integrated with smart features that provide access to a 360-degree overview of warehouse management and remote access to the inventory level. Using mobile barcode scanners, get the benefit of real-time tracking and updates of inventory on the go.

Is Your WMS Scalable and Capable to Handle Increasing Orders and Product Lines?

Yes, our WMS (Warehouse Management System) is highly scalable and capable of efficiently handling increasing orders and expanding product lines.

What is the Cost of Warehouse Inventory Management Solution?

Warehouse and Inventory management solutions can be widely expensive or very affordable. The cheap option of WMS is available for free with limited orders and functionality and may charge thousands of dollars per month for full access.

But before you hesitate to get your hands away by being afraid of expensive price tags, keep in mind that most warehouse and inventory management solutions are less expensive than ERP solutions like “RockEye Warehouse and Inventory Management Solution” which help you save 95% of your warehouse complexities.

How to Select the Best Warehouse Inventory Management Solution?

You need to evaluate your business requirements and complexities to choose the best warehouse inventory management solution. But still here are the few parameters that you can evaluate before choosing the Warehouse Inventory Management Solution:

– Make sure it has all the advanced features like real-time monitoring, modular UI/UX design, location tracking, multi-warehouse support, remote access, and more.

– Supporting multiple payment methods to ensure excellent customer satisfaction.

– Easy scalability and capability to handle increasing order requests and product listing.

You can also check our other services:

Hire Web Developers In India, Hire Laravel Developers In India, Hire PHP Developers In India, Hire Flutter Developers In India, Hire React Native Developers In India, Hire Android App Developers In India, Hire iOS App Developers In India, Hire ReactJs Developers In India, Hire NodeJs Developers In India, Hire AngularJs Developers In India, Hire ASP.NET Developers In India, Software Product Development Company In India, Web Development Company In India, Mobile App Development Company In India, Angular Development Company In India, Laravel Development Company In India, iOS App Development Company In India, Android App Development Company in India