Table of Contents

While a flywheel helps to stabilize machine movement, AI in manufacturing is key to keeping up with industry changes and trends, boosting efficiency, and reducing interruptions in the production process. As digital transformation is a cornerstone of survival for business, integrating AI is forging new horizons of enhanced customer experience and reduced operations costs. Consequently, this is precisely what businesses are predominantly seeking.

Before we dive in and further peek into the transformation journey AI can drive to your business, let’s look at some of the insights.

How Is AI in Manufacturing Transforming the Industries?

Let’s check some statistics and understand how you could fuel transformation in your business to stay ahead in the competitive arena.

- Global AI marketing is expected with unprecedented growth of USD 156.1 billion by 2033 with an annual growth rate of 45%.

- Manpower combined with AI for the decision has the potential to enhance manufacturing efficiency by 20%.

- As per reports by Accenture, Artificial Intelligence would enhance 2X Annual economic growth rate and boost labor productivity by 40% by 2035.

- 29% of manufacturers would adopt AI for maintenance purposes, resulting in a 25% cost reduction and improved efficiency.

- AI and robotics technology have fueled the growth and hit 680,000 market units in 2022 and by 2031 it would be worth $150 billion bringing the paradigm shift in automation.

- McKinsey Reports Suggests, that AI Integrated has optimized supply-chain management. The early AI adopters improved logistics costs by 15% inventory by 35% and service level by 65%.

Ongoing evolution and revolution enforces to churn out most of AI. Integration of AI in an end-to-end approach can expand the potential of business, from procurement to sales and more. AI has the ability to analyze the volume of data, understand relationships, access operations, and support better decision-making. Diminishing the errors and repetitive tasks improves the productivity of humans. AI is definitely a game-changer in manufacturing and counterparts.

Ready to revolutionize the manufacturing

business?

Hire our developers and drive growth.

Leveraging AI in Manufacturing

Artificial Intelligence technology has already embarked on a few notable milestones. AI in manufacturing has the power to automate and revolutionize the operations and the entire ecosystem. Manufacturing units undertake a lot of tasks be it prototype designing, development, supply chain management, procurement, facilitating remote monitoring, and much more.

Manufacturers combine machine learning (ML) and deep learning neural networks to streamline processes, analyze data, and drive better decisions.

AI Is Combined With the Following Technologies To Churn Out Better Results:

Machine Learning – Backed with algorithms and data to understand the patterns without having prior knowledge or programming to do so.

Deep Learning – Collaborating with machine learning to understand neural networks and interpret images and videos.

Autonomous objects – Collaborative robots or connected vehicles manage the repetitive tasks on their own.

The convergence of these technologies has industries to harness their potential with AI for optimized operations, reducing costs, diminishing errors, improving safety, and creating intelligent and adaptive systems.

Game-Changing Benefits of AI in Manufacturing

Image Courtesy – Google Cloud.

Predictive Maintenance

As per the U.S. Department of Energy and Data, post-AI predictive maintenance, the downtime is reduced from 35% to 45%. Unplanned downtime and maintenance are huge contributors to declining profits and productivity. With AI-powered predictive maintenance undertakes data from machine learning, and sensor data from machinery to predict early chances of machine breakdown.

A well-orchestrated predictive maintenance would reduce equipment failures, delete overtime costs, optimize the operation of equipment, and support downstream maintenance before it is needed.Smart Quality Control

Machine learning can early detect anomalies in products and packaging. Early intervention can stop defective or decreased quality products from leaving the facility. These improvements are 90% better than human inspection and are feasible using deep-learning-based systems.

Even small businesses with few gadgets (cameras and powerful computers) can sift visuals of good and defective products.Enhanced Efficiency

Beyond efficient and scalable production, Scarp reduction is expensive for industry. The higher scrape rate denotes that the company is suffering from quality control issues and a lower level of operational efficiency.

AI defect detection methodologies can accurately detect the defect better than traditional image processing methods and humans. Be it construction or automobile manufacturing systems, they can detect anomalies before they damage other products or waste more materials.Supply Chain Optimization

With unpredictable trends and demands, businesses often suffer from deadstock or overstock. Effective supply chain management is crucial to optimize the flow of products and services while improving the bottom line.

From procuring raw goods to managing suppliers and automating warehouse processes, records of raw materials, and more. At every stage, AI can predict demand, adjust stock levels, and manage inventories reducing the chances of errors.

Integrating and leveraging AI can automate manual tedious tasks, and improve accuracy, efficiency, and sustainability. As per research, 36% of companies have already accumulated the benefits of AI solutions in their supply chain management.Cost Saving

On-time delivery, better efficiency, reduced product cycle time, and diminished errors overall translate to cost reduction. Automating the overall process would reduce human intervention promoting productivity and reducing costs.

Automating would translate to greater speed, accuracy, and a higher level of productivity which would reflect the operational costs.Training and Adoption

No matter the industry, it’s essential to stay ahead with the latest trends and adoption of technology. But with AI majority of work is streamlined and smooth. Generative AI models help in creating synthetic training data to upskill the manufacturing workforce and automate report generation, providing data insights and recommendations.Data Management

Manufacturers have ubiquitous unstructured data. The accurate, consistent, clean, and valuable data plays a critical role. With AI and ML efficiency can improve authoritative sources of truth and critical business data ensuring all the systems and processes have unified or single-channel information for generating meaningful insights and predictions.

No more tedious and errored paperwork, with AI in manufacturing, things are simplified and can improve overall performance.Improved Factory Layout

Factory Layout is a contributor to the efficiency and productivity of the whole process. Gauging the optimal factory layout, and designing the shop floor for efficiency is complicated. But with AI the factory floor layout identifies inefficiency, removes bottlenecks, and overall improves throughput.

Once the changes are integrated, AI can streamline the process and provide managers with site traffic, enabling rapid experimentation with minimal disruption.

changes are in place, AI can provide managers with a real-time view of site traffic, enabling rapid experimentation without much disruption.

Use Cases of AI in Manufacturing

Intrigued by exploring real-world applications of AI in manufacturing? Dive into our case studies showcasing how industry leaders harness AI to streamline operations and boost business productivity.

Cobots – A Collaborative Effort for Enhanced Manufacturing

The manufacturing segment undergoes tedious and mundane tasks. But equally, it requires precision and accuracy to keep everything in the loop. AI can fuel operations and drive better growth.

For Instance, Ford, a leader in the Automotive Industry has deployed a team of cobots in their assembly plant for better production. Collaborating with humans, cobots performed welding, gluing, and quality control tasks. Six cobots together sand the entire body surface of the car in 35 seconds which is a huge one.

Cobots are designed to learn different tasks. From finding and fetching things to moving and fixing things, cobots alongside humans can improve overall efficiency.Quality Control – Building better product quality

As mentioned, scrap, loss of invaluable resources, and improving manufacturing yield are key elements that need to be looked at. Streamlining and maintaining it without fueling the costs is also a matter of concern. AI has driven benefits of quickly spotting defects or poor quality, optimizing products, and analyzing the patterns to avoid further mishaps.

Numerous industries have reaped the benefits, one of them being the Food and Beverage industry. FMGC are high-speed in nature and require quality assurance at the same time. Equipment breakdown and failures can occur at any stage. With the integration of AI and predictive maintenance, businesses could diminish the cost of a breakdown.

Renowned PepsiCo’s Frito-Lay has gained 4,000 hours of manufacturing capacity through AI and experienced reduced unplanned downtime.Product Designing – Meeting the demands and needs of consumers

Gone are the days when basic and monotone concepts were working to attract consumers. With the innovation of artificial intelligence, the industry has tried and tested numerous visual artistry to uplift their products. Integrating Generative AI tools not only helps in better product design but mitigates the potential pitfalls.

From market research to concept development and testing, AI connects the dots, grasps the data, analyzes, and leverages the potential to bring out a product that aligns with the needs and requirements of the users.

NVIDIA used Generative AI in one of the complex engineering efforts of designing semiconductors. The intricate architecture of chips consists of billions of transitions that require precision and details. NVIDIA trained LLM on internal data to build assistance and increase productivity.

The Machine learning models yield better results and reduce waste. The AI-driven analytics improved the equipment maintenance schedules, reducing downtime.Product Safety and Reliability

AI has proven a huge impact on reducing manufacturing negligence and producing safe products for consumers. Be it as an automobile manufacturer or an oil and gas company, despite safety protocols industries are prone to mishaps. With intelligence-based cameras and sensors, AI can detect irregularities quickly and accurately, improving the product’s time to market. AI-assisted cameras are more diligent compared to naked eyes and can detect early anomalies.

A lively example of Tesla cars that used AI and machine learning to bring out autonomous driving technology and improve product safety and reliability. Shell Oil and Gas has brought solutions in incredible ways with AI to some of its most pressing challenges. From precision drilling, charging efficiency, monitoring forecourts, and detecting anomalies. This overall has reduced their manpower, monetizing resources and improving efficiency.Performance Optimization

Artificial Intelligence has been proven to enhance performance. AI is able to take up and analyze vast amounts of data, including historical records and real-time sensor data to understand patterns and detect anomalies and insights. In turn, it optimizes the operations, minimizes downtime, and improves the efficiency of the equipment.

GE Integrated AI in the manufacturing process resulting in potential equipment issues, addressing maintenance needs, and overall streamlined operations. This approach reduced downtime and enhanced the overall efficiency of manufacturing. By leveraging AI the company met the high performance standards and higher production goals.No Human Intervention

Though human intervention is a must, there are few industries that can be automated and operated without human presence or intervention. Robots are used to automate manual tasks and reduce errors. Integration of machine learning and predictive analytics, robots augment their ability to work.

Japan’s factor FANUC has demonstrated the capability to function autonomously for 30 days without human intervention. This approach was adopted by the Philips factory operating in the Netherlands producing electric razors with only nine employees. This model is cost-reducing, higher in productivity, and equally efficient.Reduced Manual Documenting

AI and machine learning combined have automated various tedious and mundane tasks. One of them is Robotic process automation. Traditionally, manufacturing involves lots of data, be it handling documents, recording purchases, raw materials, and more, which is time-consuming and prone to error, leading to inefficiency.

AI and machine learning combined have automated various tedious and mundane tasks. One of them is Robotic process automation. Traditionally, manufacturing involves lots of data, be it handling documents, recording purchases, raw materials, and more, which is time-consuming and prone to error, leading to inefficiency.

Whirlpool integrated Robotic Process Automation to overcome the challenge of data management and manufacturing processes. Repetitive and mundane tasks were carried out by RPA bots that ensured accuracy and productivity in the process. Additionally, whirlpool employed these bots for quality control inspections, utilizing automation, and improving uniformity and accuracy in the final product.

Fuel Your Growth Like Industry Giants and Revolutionize Your Growth With Our AI/ML Services.

In a Nutshell, Agile, data-centric, and automation are key to surviving in the competitive arena. Manufacturing is prone to obstacles and hindrances, with numerous challenges and everyday bottlenecks that could impede. The innovative and revolutionized era calls for AI in manufacturing to drive growth and weigh opportunities.

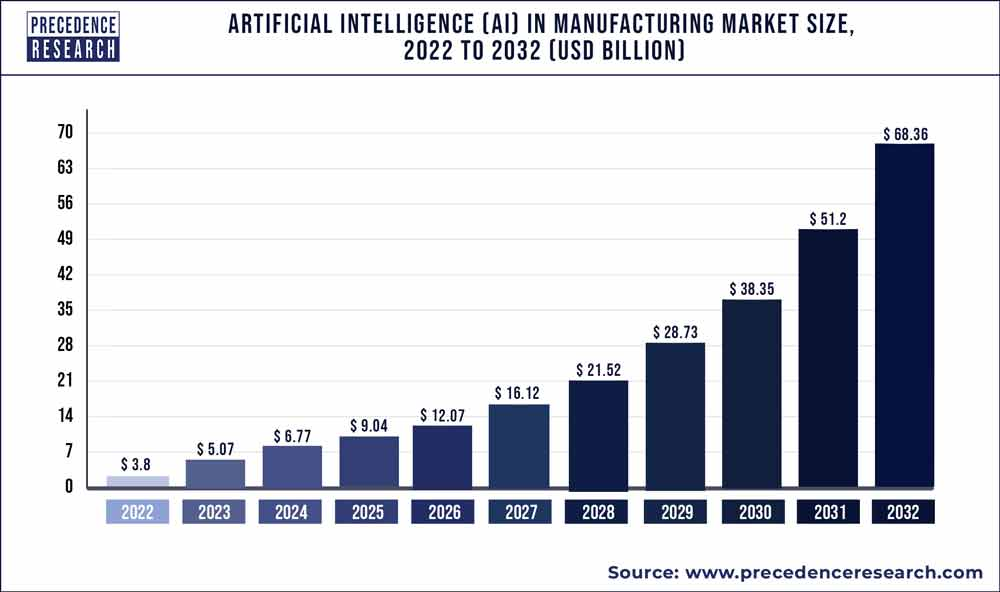

Looking ahead, AI in manufacturing is evolving and in the future, it’s going to bring a multifaceted approach to enhance operations efficiency, safety, and security. AI in manufacturing is poised to grow by $21 billion. If you are ready to dive into the market and bag profits by harnessing AI, Hidden Brains stands to be a collaborative partner in your success.

Ready to lead a future with minimal challenges?

Here are Our Expert AI/ML Developers to Assist You!Boost Productivity and Profits using AI in Manufacturing with Hidden Brains

Hidden Brains’ expertise and knowledge combined would bring new dimensions to manufacturing. Be it the healthcare sector or energy solutions, we leverage our deep skills and artificial intelligence technologies to fine-tune and build task-specific models. We have a dedicated team that will walk with you throughout to build a solution that meets your goals and needs.

FAQs

Now you have comprehensive information and insights about AI in manufacturing. And still, have some dilemmas? Well, we have got you covered. Remember, our experts are just a call away. Feel free to discuss your thoughts.

1. What are the Latest Trends of AI in Manufacturing?

AI is matured but there are many advancements still every day to automate and streamline the tasks. From predictive maintenance and quality control to data security and cobots, AI is reshaping every aspect of the manufacturing process. Industry 4.0 journey fuels innovation and heralds a new era of development and transformation. By embracing trends you can yield higher production rates, fewer supply chain disruptions, and lower costs.

2. Which Top-giants have Integrated AI in Manufacturing?

The list of giants is not limited. The development and deployment of numerous cutting-edge artificial intelligence applications have marked their footprints in every industry. Some leaders like Ford, Siemens, NVIDIA, GE, Honeywell, PepsiCo, and more have harnessed the potential of AI.

3. What AI is used in Manufacturing?

From machine learning to Generative AI and deep learning neuron networks, there are numerous automation processes teamed up to drive efficiency and bring value to the overall process.

4. What are the Key Market Drivers in AI Manufacturing?

Industry 4.0 is a major contributor to driving the growth of AI in manufacturing and sustaining in the future.

5. Which are the Segments Impacted by AI in the Manufacturing Cycle?

AI in manufacturing is triggering a shift and opening wide alleys of breakthroughs and efficiency. From raw material to supply chain management, AI is showcasing a transformative impact on each segment. Hence, it’s a game-changer and would bring a huge impact on manufacturing.